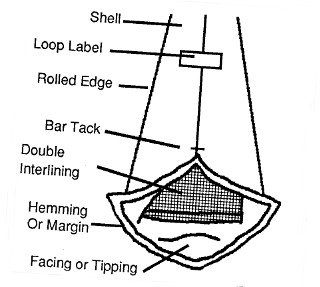

Parts of a Neck Tie

A neck tie has essentially 7 recognizable parts.

|

They consist of:

|

|

The Shell

The look of the tie is the sole responsibility of the shell.

This is the material that ultimately sells the tie.

If your shell is ugly, the rest of the construction has no significance to the rest of the tie because an unattractive pattern on the shell does not a customer purchase.

Unless ugly is your style.

The shell is the most expensive portion in the creation of a fine tie. So in order to get the most out of the fabric, a worker must be skilled in the art of cutting fabric to yield the most ties out of the least amount of material, correctly on bias, as possible.

Interlining

The interlining is also known as the blanket. It is too cut on a bias. This is the part of the tie that is heavy and gives the tie its shape, feel, weight, and knot-ability.

Interlinings and shells complement each other. A heavier lining balances out a lighter shell and conversely a heavier shell requires a lighter lining.

Facing or Tipping

This is the fabric that is on the underside of the shell. This fabric is usually smooth and provides a protective covering to the back of the shell so that when you turn over the tie you don’t view the rough and unsightly under siding of the shell.

This joining of the two materials create the Hemming or Margin.

Loop Label

The loop label, also called the care label, contains the information about the fabric content and country of origin the tie was manufactured in.

In the U.S., ties are exempt from requiring this information; however it will be affixed to all of Chichi’s Ties with the appropriate information as to the makeup of your tie, regulations or otherwise.

Bar Tack Stitch

A bar tack stitch is added to reinforce the slip stitching which joins the tie together.

Rolled Edge

The rolled edge is the fold or crease that is created to join the front and back of the tie together.

How all of these facets come together is outlined here….